Biodiesel Day 2025 is on Tuesday, March 18, 2025: What are peoples thoughts on Biodiesel?

Tuesday, March 18, 2025 is Biodiesel Day 2025. National Biodiesel Day! National Biodiesel Day!

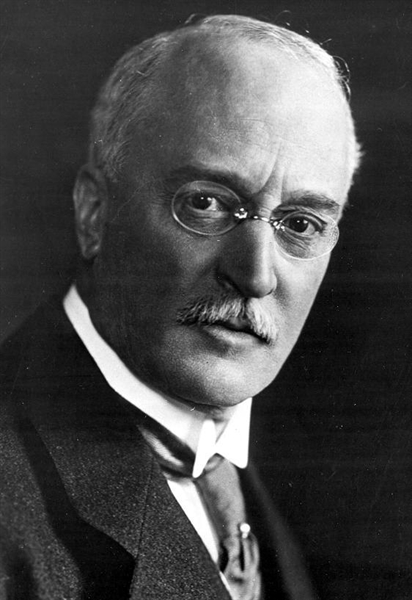

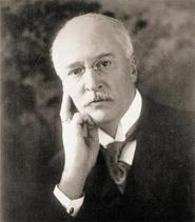

Celebrate the birth of Rudolph Diesel and the vision of utilizing vegetable oil as fuel on Biodiesel Day by switching to biodiesel fuel and energy.

Biodiesel

Biodiesel is an alternative to petroleum-based diesel fuel and is made from renewable resources such as vegetable oils or animal fats. Chemically, it is a fuel comprised of a mix of mono-alkyl esters of long chain fatty acids. A lipid transesterification production process is used to convert the base oil to the desired esters and remove free fatty acids. After this processing, unlike straight vegetable oil, biodiesel has very similar combustion properties to petroleum diesel, and can replace it in most current uses. However, it is most often used as an additive to petroleum diesel, improving the otherwise low lubricity of pure ultra low sulfur petrodiesel fuel. It is one of the possible candidates to replace fossil fuels as the world's primary transport energy source, because it is a renewable fuel that can replace petrodiesel in current engines and can be transported and sold using today's infrastructure. Biodiesel use and production is increasing rapidly, especially in Europe, the United States, and Asia, though in all markets it still makes up a small percentage of fuel sold. A growing number of fuel stations are making biodiesel available to consumers, and a growing number of large transport fleets use some proportion of biodiesel in their fuel.

Biodiesel is non-flammable, and in contrast to petroleum diesel it is non-explosive, with a flash point of 150 °C for biodiesel as compared to 64 °C for petrodiesel. Unlike petrodiesel, it is biodegradable and non-toxic, and it significantly reduces toxic and other emissions when burned as a fuel. The most common form uses methanol to produce methyl esters, though ethanol can be used to produce an ethyl ester biodiesel. A byproduct of the transesterification process is the production of glycerol.

Currently, biodiesel is more expensive to produce than petroleum diesel, which is often stated as the primary factor keeping it from being in more widespread usage. It is also more likely to gel, making it unable to flow, which limits its use in pure form in cold climates. Current worldwide production of vegetable oil and animal fat is not enough to replace liquid fossil fuel use. Some environmental groups, notably the NRDC (Natural Resources Defense Council), object to the vast amount of farming and the resulting over-fertilization, pesticide use, and land use conversion that would be needed to produce the additional vegetable oil.

History

Transesterification of a vegetable oil was conducted as early as 1853, by scientists E. Duffy and J. Patrick, many years before the first diesel engine became functional. Rudolf Diesel's prime model, a single 10 ft (3 m) iron cylinder with a flywheel at its base, ran on its own power for the first time in Augsburg, Germany on August 10, 1893. In remembrance of this event, August 10 has been declared International Biodiesel Day. Diesel later demonstrated his engine at the World Fair in Paris, France in 1898. This engine stood as an example of Diesel's vision because it was powered by peanut oil—a biofuel, though not strictly biodiesel, since it was not transesterified. He believed that the utilization of a biomass fuel was the real future of his engine. In a 1912 speech, Rudolf Diesel said, "the use of vegetable oils for engine fuels may seem insignificant today, but such oils may become, in the course of time, as important as petroleum and the coal-tar products of the present time."

During the 1920s, diesel engine manufacturers altered their engines to utilize the lower viscosity of the fossil fuel (petrodiesel) rather than vegetable oil, a biomass fuel. The petroleum industries were able to make inroads in fuel markets because their fuel was much cheaper to produce than the biomass alternatives. The result was, for many years, a near elimination of the biomass fuel production infrastructure. Only recently have environmental impact concerns and a decreasing cost differential made biomass fuels such as biodiesel a growing alternative.

In the 1990s, France launched the local production of biodiesel fuel (known locally as diester) obtained by the transesterification of rapeseed oil. It is mixed to the proportion of 5% into regular diesel fuel, and to the proportion of 30% into the diesel fuel used by some captive fleets (public transportation). Renault, Peugeot, and other manufacturers have certified truck engines for use with up to this partial biodiesel. Experiments with 50% biodiesel are underway.

From 1978 to 1996, the U.S. National Renewable Energy Laboratory experimented with using algae as a biodiesel source in the "Aquatic Species Program". A recent paper from Michael Briggs at the UNH Biodiesel Group, offers estimates for the realistic replacement of all vehicular fuel with biodiesel by utilizing algae that has a greater than 50% natural oil content.

Fuel quality, standards and properties

Biodiesel is a clear amber-yellow liquid with a viscosity similar to petrodiesel (the industry term for diesel produced from petroleum). Much of the world uses a system known as the "BD factor" to state the amount of biodiesel in any fuel mix, in contrast to the "BA" system used for bioalcohol mixes. For example, 20% biodiesel is labeled BD20. Pure biodiesel, 100%, is referred to as BD100. In the United States, a similar system is used, but the "D" is dropped (B100, B20, B5, etc.).

The international standard for biodiesel is ISO 14214. Another is the ASTM International standard ASTM D 6751, which is the most common standard referenced in the United States. In Germany, the requirements for biodiesels are fixed in a DIN standard. There are standards for three different varieties of biodiesel, which is made of different oils:

RME (rapeseed methyl ester, from rape products, according to DIN E 51606)

PME (vegetable methyl ester, purely vegetable products, according to DIN E 51606)

FME (fat methyl ester, vegetable and animal products, according to DIN V 51606)

The standards make sure that the following important factors in the fuel production process are satisfied:

Complete reaction.

Removal of glycerin.

Removal of catalyst.

Removal of alcohol.

Absence of free fatty acids.

The basic industrial tests to see if the product conforms to the standard typically includes gas chromatography that verifies only the more important of the variables above. More complete testings cost more. Fuel meeting the quality standards is very non-toxic, with a toxicity rating (LD50) of greater than 50 ml/kg. This translates to greater than 3 liters having to be consumed for an average 60 kg person to cause death 50% of the time. The common comparison is that this makes biodiesel ten times less toxic than table salt.

Biodiesel can be mixed with petroleum diesel at any concentration in most modern engines, although it has the disadvantage of degrading rubber gaskets and hoses in older vehicles (prior to 1992). Biodiesel is a better solvent than petrodiesel and has been known to break down deposits of residue in the fuel lines of vehicles which usually run on petroleum. Fuel filters may become clogged with particulates if a quick transition to pure biodiesel is made, but the biodiesel cleans the engine in the process.

In a study at a U.S. military base, a biodiesel blend was used as a replacement for heating oil at housing on the base. Due to the solvent power of biodiesel, residues that had been present in fuel tanks for decades were dissolved. The particulate component of the residues caused repeated clogging of fuel strainers, requiring repeated replacement, cleaning, and in some cases installation of higher capacity filters. Due to the relatively smaller surface area and service life of fuel tanks in motor vehicles and mobile equipment, filter clogging is less prevalent but still a factor to be considered.

Environmental benefits in comparison to petroleum based fuels include:

Biodiesel reduces emissions of carbon monoxide (CO) by approximately 50% and carbon dioxide by 78.45% on a net lifecycle basis because the carbon in biodiesel emissions is recycled from carbon that was already in the atmosphere, rather than being new carbon from petroleum that was sequestered in the earth's crust. (Sheehan, 1998)

Biodiesel contains fewer aromatic hydrocarbons: benzofluoranthene: 56% reduction; Benzopyrenes: 71% reduction.

It also eliminates sulfur emissions (SO2), because biodiesel doesn't include sulfur.

Biodiesel reduces by as much as 65% the emission of particulates (small particles of solid combustion products).

Biodiesel does produce more NOx emissions than petrodiesel, but these emissions can be reduced through the use of catalytic converters. Petrodiesel vehicles have generally not included catalytic converters because the sulfur content in that fuel destroys the devices, but biodiesel does not contain sulfur. The increase in NOx emmisions may also be due to the higher cetane rating of biodiesel. Properly designed and tuned engines may eliminate this increase.

It has a higher cetane rating than petrodiesel, and therefore ignites more rapidly when injected into the engine.

Pure biodiesel (BD100 or B100) can be used in any petroleum diesel engine, though it is more commonly used in lower concentrations. Some areas have mandated ultra-low sulfur diesel (ULSD) petroleum, which reduces the natural viscosity and lubricity of the fuel because the sulfur and certain other materials have been removed. Additives are required to make it properly flow in engines, and biodiesel is one popular alternative. Ranges as low as 2% (BD2 or B2) have been shown to restore lubricity. Also, many municipalities have started using 5% biodiesel (BD5 or B5) in snow-removal equipment and other systems.

Since biodiesel is more often used in a blend with petroleum diesel, there is less information and formal studies about the effects on pure biodiesel in unmodified engines and vehicles in actual use. Fuel meeting the standards and engine parts that can withstand the greater solvent properties of biodiesel is expected to, and in reported cases does, run without any additional problems over petroleum diesel.

The gel point of biodiesel varies depending on the proportion of different types of esters that it contains. However, most biodiesel including that made from soybean oil has a somewhat higher gel and cloud point than petroleum diesel. In practice this often requires the heating of storage tanks, especially in colder climates.

Production

Main article: Biodiesel production

Base oils

A variety of biolipids can be used to produce biodiesel. These include:

Virgin oil feedstock; rapeseed and soybean oils are most commonly used, though other crops such as mustard, palm oil, hemp and even algae show promise;

waste vegetable oil (WVO);

Animal fats including tallow, lard, and yellow grease.

Many advocates suggest that waste vegetable oil is the best source of oil to produce biodiesel. However, the available supply is drastically less than the amount of petroleum-based fuel that is burned for transportation and home heating in the world. According to the United States Environmental Protection Agency (EPA), restaurants in the US produce about 300 million gallons of waste cooking oil annually. Although it is economically profitable to use WVO to produce biodiesel, it is even more profitable to convert WVO into other products such as soap. Hence, most WVO that is not dumped into landfills is used for these other purposes. Animal fats are similarly limited in supply, and it would not be efficient to raise animals simply for their fat. However, producing biodiesel with animal fat that would have otherwise been discarded could replace a small percentage of petroleum diesel usage.

The estimated transportation fuel and home heating oil use in the United States is about 230,000 million gallons. (Briggs, 2004) Waste vegetable oil and animal fats would not be enough to meet this demand. In the United States, estimated production of vegetable oil for all uses is about 23,600 million pounds (12,000,000 t) or 3,000 million US gallons (11,000,000 m³)), and estimated production of animal fat is 11,638 million pounds (5,000,000 t). (Van Gerpen, 2004)

For a truly renewable source of oil, crops or other similar cultivatable sources would have to be considered. Plants utilize photosynthesis to convert solar energy into chemical energy. It is this chemical energy that biodiesel stores and is released when it is burned. Therefore plants can offer a sustainable oil source for biodiesel production. Different plants produce usable oil at different rates. Some studies have shown the following annual production:

Soybean: 40 to 50 US gal/acre (40 to 50 m³/km²)

Rapeseed: 110 to 145 US gal/acre (100 to 140 m³/km²)

Mustard: 140 US gal/acre (130 m³/km²)

Jatropha: 175 US gal/acre (160 m³/km²)

Palm oil: 650 US gal/acre (610 m³/km²)

Algae: 10,000 to 20,000 US gal/acre (10,000 to 20,000 m³/km²)

The production of algae to harvest oil for biodiesel has not been undertaken on a commercial scale, but working feasibility studies have been conducted to arrive at the above number. Specially bred mustard varieties can produce reasonably high oil yields, and have the added benefit that the meal leftover after the oil has been pressed out can act as a effective and biodegradable pesticide. There is ongoing research into finding more suitable crops and improving oil yield. Using the current yields, vast amounts of land would have to be put into production to produce enough oil to completely replace fossil fuel usage.

Soybeans are not a very efficient crop solely for the production of biodiesel, but their common use in the United States for food products has led to soybean biodiesel becoming the primary source for biodiesel in that country. Soybean producers have lobbied to increase awareness of soybean biodiesel, expanding the market for their product. In Europe, rapeseed is the most common base oil used in biodiesel production. In India and southeast Asia, the Jatropha tree is used as a significant fuel source, and it is also planted for watershed protection and other environmental restoration efforts.

Efficiency and economic arguments

According to a study written by Drs. Van Dyne and Raymer for the Tennessee Valley Authority, the average US farm consumes fuel at the rate of 82 litres per hectare (8.75 US gallons per acre) of land to produce one crop. However, average crops of rapeseed produce oil at an average rate of 1,029 L/ha (110 US gal/acre), and high-yield rapeseed fields produce about 1,356 L/ha (145 US gal/acre). The ratio of input to output in these cases is roughly 1:12.5 and 1:16.5. Photosynthesis is known to have an efficiency rate of about 16% and if the entire mass of a crop is utilized for energy production, the overall efficiency of this chain is known to be about 1%. This does not compare favorably to solar cells combined with an electric drive train. Biodiesel outcompetes solar cells in cost and ease of deployment. However, these statistics by themselves are not enough to show whether such a change makes economic sense.

Additional factors must be taken into account, such as: the fuel equivalent of the energy required for processing, the yield of fuel from raw oil, the return on cultivating food, and the relative cost of biodiesel versus petrodiesel. A 1998 joint study by the U.S. Department of Energy (DOE) and the U.S. Department of Agriculture (USDA) traced many of the various costs involved in the production of biodiesel and found that overall, it yields 3.2 units of fuel product energy for every unit of fossil fuel energy consumed. That measure is referred to as the energy yield. A comparison to petroleum diesel, petroleum gasoline and bioethanol using the USDA numbers can be found at the Minnesota Department of Agriculture website. In the comparison petroleum diesel fuel is found to have a 0.843 energy yield, along with 0.805 for petroleum gasoline, and 1.34 for bioethanol. The 1998 study used soybean oil primarily as the base oil to calculate the energy yields. It is conceivable that higher oil yielding crops could increase the energy yield of biodiesel.

Some nations and regions that have pondered transitioning fully to biofuels have found that doing so would require immense tracts of land if traditional crops are used. Considering only traditional plants and analyzing the amount of biodiesel that can be produced per acre of cultivated land, some have concluded that it is likely that the United States, with one of the highest per capita energy demands of any country, does not have enough arable land to fuel all of the nation's vehicles. Other developed and developing nations may be in better situations, although many regions cannot afford to divert land away from food production. For third world countries, biodiesel sources that use marginal land could make more sense, e.g. honge nuts grown along roads.

More recent studies using a species of algae that has oil contents of as high as 50% have concluded that as little as 28,000 km? or 0.3% of the land area of the US could be utilized to produce enough biodiesel to replace all transportation fuel the country currently utilizes. Further encouragement comes from the fact that the land that could be most effective in growing the algae is desert land with high solar irradiation, but lower economic value for other uses and that the algae could utilize farm waste and excess CO2 from factories to help speed the growth of the algae.

The direct source of the energy content of biodiesel is solar energy captured by plants during photosynthesis. The website biodiesel.co.uk discusses the positive energy balance of biodiesel:

When straw was left in the field, biodiesel production was strongly energy positive, yielding 1 GJ biodiesel for every 0.561 GJ of energy input (a yield/cost ratio of 1.78).

When straw was burned as fuel and oilseed rapemeal was used as a fertilizer, the yield/cost ratio for biodiesel production was even better (3.71). In other words, for every unit of energy input to produce biodiesel, the output was 3.71 units (the difference of 2.71 units would be from solar energy).

Biodiesel is becoming of interest to companies interested in commercial scale production as well as the more usual home brew biodiesel user and the user of straight vegetable oil or waste vegetable oil in diesel engines. Homemade biodiesel processors are many and varied.

Availability

Biodiesel is commercially available in most oilseed-producing states in the United States. At this time, it is considerably more expensive than fossil diesel, though it is still commonly produced in relatively small quantities (in comparison to petroleum products and ethanol). Many farmers who raise oilseeds use a biodiesel blend in tractors and equipment as a matter of policy, to foster production of biodiesel and raise public awareness. It is sometimes easier to find biodiesel in rural areas than in cities. Similarly, some agribusinesses and others with ties to oilseed farming use biodiesel for public relations reasons. As of 2003 some tax credits are available in the U.S. for using biodiesel. In 2004 almost 30 million gallons (110,000,000 l) of commercially produced biodiesel were sold in the U.S., up from less than 0.1 million US gallons (380,000 l) in 1998. Due to increasing pollution control requirements and tax relief, the U.S. market is expected to grow to 1 or 2 billion US gallons (4,000,000,000 to 8,000,000,000 l) by 2010. The price of biodiesel has come down from an average $3.50 per US gallon ($0.92/l) in 1997 to $1.85 per US gallon ($0.49/l) in 2002. However this is still higher than petrodiesel which averaged about $0.85 per US gallon ($0.22/l) in 2002 before road tax is added.

Brazil opened a commercial biodiesel refinery in March 2005. It is capable of producing 12 million liters (3.2 million gallons) per year of biodiesel fuel. Feedstocks can be a variety of sunflower seeds, soybeans, or castor beans. The finished product will be currently a blend of gas oil with 2% biodiesel and, after 2011, 5% biodiesel, both usable in unmodified diesel engines.

YOU WANT TO KNOW HOW TO MAKE IT?? READ BELOW!!!!

Biodiesel recipe

Like a recipe for making a cake, a biodiesel recipe specifies a quantity of every ingredient required, and the steps for combining and processing them to make biodiesel fuel.

The most common recipe uses waste vegetable oil (WVO), alcohol (methanol or ethanol) and sodium hydroxide (caustic soda), to produce biodiesel and glycerol. To produce 1 t of biodiesel:

One needs 1 t of biolipids (animal or vegetable oil) and 0,1 t of methanol.

One receives 0,1 t of glycerol.

The most common steps are:

Preparation: cleaning/heating biolipid (i.e. WVO). With wet oil, you will obtain soap with the biodiesel, the conversion index from vegetable oil to biodiesel will be smaller and you will obtain an excess of triglycerides.

Titration of WVO sample. Optimal pH for Biodiesel is 7 (neutral), the same as distilled water (and most tap water). Some fat has a high level of free fatty acids which require an acid esterification (to obtain an pH lower than 3) before the alkaline transesterification.

Mixing the bioalcohol (methanol or ethanol) and catalyst (sodium hydroxide) in exact amounts, to produce methoxide

Combining at 50?C methoxide with the biolipids.

Separation:

Of biodiesel and glycerol (by decantation, centrifugation...).

Removing of alcohol (by distillation).

Biodiesel purification: separation from the biodiesel of the wastes (catalyst and soap): washing and drying the biodiesel.

Disposing of the wastes.

There are three basic routes to biodiesel production from biolipids (biological oils and fats):

Base catalyzed transesterification of the biolipid.

Direct acid catalyzed transesterification of the biolipid.

Conversion of the biolipid to its fatty acids and then to biodiesel.

Almost all biodiesel is produced using base catalyzed transesterification as it is the most economical process requiring only low temperatures and pressures and producing a 98% conversion yield. For this reason only this process will be described bellow.

Transestrification is crucial for producing biodiesel from biolipids. The transesterification process is the reaction of a triglyceride (fat/oil) with an bioalcohol to form esters and glycerol.

Oil preparation

Biodiesel processor machines, need the vegetable oil to have some specific properties:

Suspended particles lower than 1% (mass/mass) and than 5 micrometers. Because of this, the following are necessary:

Filtration to 5 micrometers.

Washing with hot water.

Decantation.

Heating of the oil.

Second decantation.

Anhydrous (waterless). Because of this, the final step of preparation, after the second decantation is drying.

Easy solubility in the alcohol to use.

Reaction

The reaction may be shown

CH2COOR1

Biodiesel Question Please help?

5 microns would do for a final filter but you should do a bigger prefilter if you can.

The water after is is made will settle to the bottom or it should any way. It may take a day or so but it should and then you can also get a water separator and filter combination if you are not sure it is all removed just to be on the safe side.

What company in the Philippines sells biodiesel to the public?

Flying V first to market biodiesel in the Philippines

First posted 06:11am (Mla time) Aug 21, 2005

By Macky M. Lopez

Inquirer News Service

Editor's Note: Published on page A12 of the August 21, 2005 issue of the Philippine Daily Inquirer

BIODIESEL is diesel blended with an additive using vegetable oil as a base. Soybean oil is used as an additive base in the United States, while rapeseed oil is used in Europe. In the Philippines, coconut oil is the raw material for the additive called coconut methyl ester (CME).

Flying V has started selling Envirotek BioActiv BD 100+, a CME-based diesel fuel enhancer in liter packs, at all its stations at P31 a liter, or 60 centavos more expensive than ordinary diesel.

The additive offers several benefits. It helps curb air pollution, reduces smoke-emission, enhances engine performance, protects the engine, strengthens acceleration, and saves on fuel.

If a jeepney covers 60 km using 10 liters of ordinary diesel, it can run 66 km using 10 liters of biodiesel. For every 50 liters of biodiesel, the jeepney driver or owner saves P130.

Flying V launched in Baguio on Aug. 1 the first Flying V Station to market pre-blended CME diesel called Envirotek Biodiesel Premium.

Print this story

Send this story

Write the editor

Reprint this article

View other stories

As part of the city’s Bantay Kalinisan Program, the City Council passed an ordinance mandating the use of the product for all diesel engine vehicles.

On Aug. 11, Flying V launched at its station in Cainta, Rizal the sale of its Envirotek Biodiesel Premium. The occasion was graced by President Macapagal-Arroyo in recognition of Flying V’s pioneering work in the sale of an alternative fuel that can help the country save on foreign exchange. On the same day, four other Flying V stations in Metro Manila started selling biodiesel.

By September, Flying V will start selling biodiesel in Davao City. Flying V is targeting to make Envirotek Biodiesel Premium available at all its stations nationwide by the end year end.

How did Flying V get into biodiesel?

On April 14, 2003, Ramon F. Villavicencio, chair of Transworld Asia Inc., which operates Flying V stations, signed a memorandum of understanding (MOU) with the United States Agency for International Development to expand the use of cleaner sources of energy for the transport sector under the agency’s clean cities program.

Based on the MOU, the Technological University of the Philippines conducted a seminar on the use of CME for the transport sector the following month. The Philippine Clean Diesel Task Force, composed of the departments of energy, environment, trade and industry, and science and technology, the Metro Manila Development Authority, and the Bureau of Product Standards endorsed a memorandum to Ms Arroyo calling for the mandatory use of CME in diesel vehicles.

In May 2003, Flying V and Chemrez Inc. entered into a distribution agreement for the sale of CME. A month after, Flying V and USAID met to discuss the launching of biodiesel. Davao was chosen as the pilot city. The Department of Energy came out with the product standards on CME in July 2004.

The DOE and USAID, meanwhile, were conducting seminars on CME at various cities. In October 2003, the Mayor of Baguio requested Flying V to coordinate with USAID for its inclusion in the clean cities program.

The President issued on Feb. 9, 2004 Memorandum Circular No. 55 mandating the use of 1 percent by volume CME on all government diesel-powered vehicles. The DOE came out with the implementing rules and regulations of MC No. 55 on March 29, 2004 to take effect on July 2004.

Help clean the air and achieve fuel savings. Load up with Envirotek Biodiesel Premium, the fuel for life.

(Macky M. Lopez is a director and spokesperson of Transworld Asia Inc. - Flying V.)